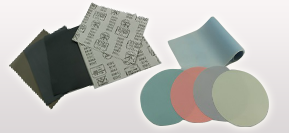

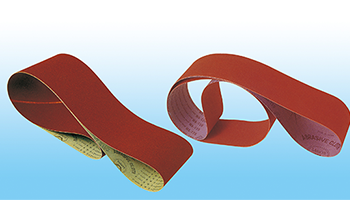

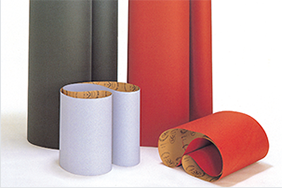

ABRASIVE HANDLED BY OUR COMPANY [FOR EACH PRODUCT]

Since the establishment of our company in 1956, we have engaged in development of abrasives and polishing materials for a wide variety of materials and applications.

As one abrasive supplier, we are able to produce abrasives in harmony with your own desired product specifications, while enhancing your workability and cost reduction.

Page Top

- GLASS

- PLASTIC

- IRON/SUS

- NON-FERROUS METAL

- TITANIUM

- CERAMIC

- PAINT WORK

- PLATING

- HIGH GRINDING

- FINAL POLISHING

- HAIRLINE FINISH

- RUST REMOVAL

- SURFACE PREPARATION

- GLASS

- PLASTIC

- IRON/SUS

- NON-FERROUS METAL

- TITANIUM

- CERAMIC

- PAINT WORK

- PLATING

- HIGH GRINDING

- FINAL POLISHING

- HAIRLINE FINISH

- RUST REMOVAL

- SURFACE PREPARATION

- GLASS

- PLASTIC

- IRON/SUS

- NON-FERROUS METAL

- TITANIUM

- CERAMIC

- PAINT WORK

- PLATING

- HIGH GRINDING

- FINAL POLISHING

- HAIRLINE FINISH

- RUST REMOVAL

- SURFACE PREPARATION

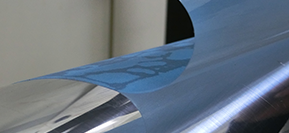

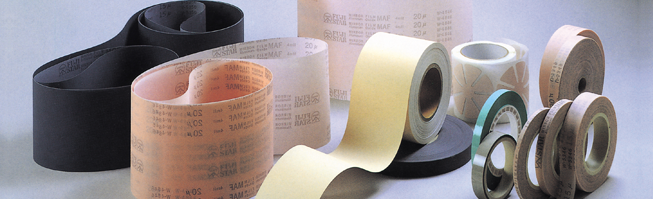

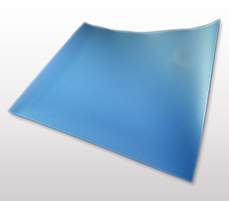

This epoch-making product can naturally be fitted on to the polishing surface (R-plane) by dry sanding, while achieving uniform finishing without causing any unevenness.

- GLASS

- PLASTIC

- IRON/SUS

- NON-FERROUS METAL

- TITANIUM

- CERAMIC

- PAINT WORK

- PLATING

- HIGH GRINDING

- FINAL POLISHING

- HAIRLINE FINISH

- RUST REMOVAL

- SURFACE PREPARATION

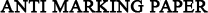

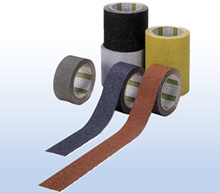

When attached to rolls for transporting printed materials, this product can serve as tape that prevents ink blots.

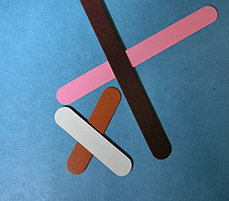

These abrasives are completely and beautifully colored by means of the same method of other abrasives and are used exclusively for nail polishing.

- GLASS

- PLASTIC

- IRON/SUS

- NON-FERROUS METAL

- TITANIUM

- CERAMIC

- PAINT WORK

- PLATING

- HIGH GRINDING

- FINAL POLISHING

- HAIRLINE FINISH

- RUST REMOVAL

- SURFACE PREPARATION