Power Train

Sankyo Rikagaku’s share of the automotive power train engine manufacturers

in Japan is 90 percent. We develop products specifically for engines,

and propose them to our customers.

Polishing will affect the hardness of the back-up material installed on the machinery. It is important to consider this when selecting the type of film used.

Also the film used will depend on how much finish roughness/smoothness in required by the customer.

Depending on the materials: In the case of steel; alumina whetstone, In the case of cast meta:l we use silicon carbide system whetstone.

As the process can affect the shape of the camshaft, to insure an identical level of roughness in is essential two steps are taken in the process.

Automobile Manufacturing

Automobile manufacturing factory application, whilst the car is drying

we have developed a product that can be used concurrently and thus contribute to bring costs down.

Painting

Intermediate coat polishing

(polishing work of underlying color)

Final Finishing Product Lineup.We used water proof film, which does not affect the paints ingredients allowing for a precision finish. Of course this method of is adopted by Japanese car manufactures

Painting

Final Finishing

(removing common surface defects)

This was achieved by completing long term R&D period.The final stage removes only small flaws, focussing on abrasion it has excellent usability.Although this focused on the polishing, there is no problem with finishing.

For more information about this product, please contact us through our online form

Contact usWe offer durable products with extended and long-term, stable usability. Precision polishing of

connector plug end face of the optical fiber in order to ensure the reliability and adhesion.

According to the customer, the conditions change, so the above processes should be used fo reference only.

SC/FC Single-Connector

MT/MPO Connector

LC/MU Single-Connector

With the goal of improving fuel consumption the body of automobiles have become lighter.

Overall rounded design is becoming mainstream. In accordance with changes in design,

our abrasive materials have been simultaneously been developed to respond to these changes.

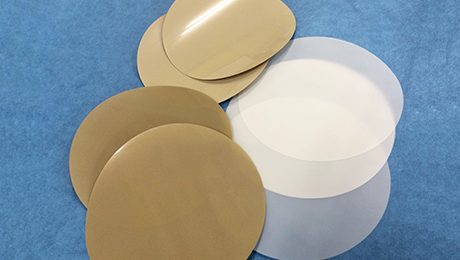

Endorsed Products

【Clog Free Soft】

Clog Free Soft creates polishing that is uniform and very well finished, producing a great feel.